UNIPLY

Continuous innovation, responsible use of natural resources, enduring commitment to quality - at every stage, and of course, its best-in-class product range is all what sets apart UNIPLY in the consumer mind space today.

Founded by a group of experts from the plywood industry in the year 1996 with a belief that Uniply could offer consumers the best quality plywood, panel products and auxiliaries, Uniply has marched on towards greater success. The brand name is now synonymous with quality and reliability.Today, Uniply has over 500 dealers throughout the country in its wide spread network. The brand is recognised and used in numerous high-end projects, and commands excellent top-of-the-mind recall.

Its close association with world-renowned manufacturers, architects, interior designers and builders, has brought to the table a remarkable value. Their continuous feedback has helped the company to grow and bring forth the best for its valuable consumers. This has indeed led to the launch of new and innovative products in line with the consumer expectations.

These practices, in addition to the use of innovative technologies and modern processes, has transformed the company as a metaphor of trustworthiness in the eyes of customers, employees, suppliers and stock holders.

From humble beginnings, Uniply is today a force to reckon with in the plywood and panel business. Our products have crossed Indian boundaries to make a mark in the foreign markets.

MURINGAKANDY is the dealer for UNIPLY in Malabar region and trades the following categories of Plywood’s.

UNIPLY PLATINUM ATS-Z PLUS

ATS PLYWOOD

Amongst various other considerations, termites are a perennial concern to anyone opting for plywood. Thanks to cutting-edge research, Uniply has developed an ideal solution - 'Platinum ATS-Z Plus' plywood. It is an innovative, industry-leading product that comes with an Anti-termite solution (ATS) protection. This product has proven to offer superior defence against termites thus, making it damage free.

TECHNICAL SPECIFICATIONS*

| Properties | Specified as per BIS 710 : 1976 |

| Adhesive for bonding | Un-extended BWP Phenol Formaldehyde Synthetic Resin as per BIS 848-1974 |

| Preservative Treatment | As Per BIS 5539 : 1969 |

| Glue Shear Strength | Excellent |

| GSS Dry State | Above 1350 N Avg. Above 1100 N Min. Individual Avg |

| GSS Wet State | Above 1000 N Avg. Above 800 N Min. Individual Avg. |

| Mechanical Data | Excellent |

| Screw Holding Strength (Kg) | >250 |

| Specific Gravity | Above 750 Kgs/Cubic Meter |

| Nail Holding Strength (Kg) | >60 |

| Modulus Of Rupture | Above 400 Kgs/cm2 |

| Tensile Strength | Excellent |

| Parallel To Grain Direction | Above 425 KN/m2 |

| Perpendicular To Grain Direction | Above 250 KN/m2 |

| Sum In Both Directions | Above 850 KN/m2 |

| Money Back Guarantee | 300% |

| Conforms to IS 710 - 1976 |

SPECIFICATIONS

- Resistance to termites and borers

- Made up of non-toxic compounds

- Boiling water resistant

- Bend and warp resistant

- Pressure treated for stiffness, lesser chances of sagging

Uniply Gold Club MARINE PLYWOOD

This plywood is perfect to construct boats, kayaks etc. Uniply's Gold Club Marine Plywood is high quality tropical hardwood bonded with un-extended BWP type phenolic resin using superior technology. The outstanding feature of this plywood is its ability to withstand drying and wetting, making it an ideal choice for boats, roofing and other outdoor applications where it's exposed to water for a prolonged period.

This plywood is perfect to construct boats, kayaks etc. Uniply's Gold Club Marine Plywood is high quality tropical hardwood bonded with un-extended BWP type phenolic resin using superior technology. The outstanding feature of this plywood is its ability to withstand drying and wetting, making it an ideal choice for boats, roofing and other outdoor applications where it's exposed to water for a prolonged period.TECHNICAL SPECIFICATIONS*

| Properties | Specified As Per BIS 710- 1976 |

| Adhesive for bonding | Phenol Formaldehyde Synthetic Resin As Per BIS 848-1974 |

| Preservative Treatment | As Per BIS 5539 - 1969 |

| Glue Shear Strength | |

| GSS Dry State | 1350 N Avg. 1100 N Min. Individual Avg. |

| GSS Wet State | 1000 N Avg. 800 N Min. Individual Avg |

| Mechanical Data | |

| Screw Holding Strength (Kg) | 250 |

| Specific Gravity | 750 kgs/Cubic Meter |

| Nail Holding Strength (Kg) | 60 |

| Modulus Of Rupture | 400 Kgs/cm2 |

| Tensile Strength | |

| Parallel To Grain Direction | 425 KN/m2 |

| Perpendicular To Grain Direction | 250 KN/m2 |

| Sum In Both Directions | Minimum 850 KN/m2 |

| Stands 72 hours soaking at 100°C | |

| Conforms to IS 710 - 1976 |

SPECIFICATIONS

- Boiling Water Resistant

- Bend Resistant

- Life time guarantee*

- Withstands all climatic conditions

- Pressure treated for stiffness, lesser chances of sagging

APPLICATIONS

- Boats

- Heat Exchangers

- Sign boards

- Marine and river crafts

- Public hoardings

- Roofing and other severely exposed outdoor structures

UNIPLY BWR

BOILING WATER RESISTANT

Is your kitchen falling apart due to constant exposure to moisture? Then opting for Uniply's BWR plywood will be your best decision. It is chemically treated, made of high quality tropical hardwood, comes with a long panel and phenolic glue core veneers. Each veneer is treated with preservatives prior to pressing ensuring uniform distribution of moisture and adhesive. So now, instead of worrying, you can enjoy cooking your favourite dishes.TECHNICAL SPECIFICATIONS*

| Properties | Specified as per IS 303 : 1989 |

| Adhesive for bonding | Phenol Formaldehyde as per BIS 848 : 1974 |

| Preservative Treatment | as per IS 5539 : 1969 |

| Specific Gravity | 750 Kg/Cubic Meter |

| Water Resistance Test | |

| Stands soaking at 100°C for 72 hours and oven dry at 65 C for 16 hours (3 cycle) | |

| Conforms to IS 303 : 1989 |

SPECIFICATIONS

- Preservative treated for uniform moisture distribution and adhesive

- Boiling Water Resistant

- Resistant to termites and powdering

- Made from high quality tropical hardwood

APPLICATIONS

- Partition and panelling

- Panel insert in doors

- False ceiling

- Cavity flooring

- Cupboard shelving and shutters

- Kitchen cabinet

- Bus body building

- Railway coaches

- Sign boards

- Milk booths and stalls

- Furnitures

UNIPLY HMR

HIGH MOISTURE RESISTANT

If factors such as rain and high humidity are causing havoc on your wood then Uniply's high moisture resistant plywood would be a sensible choice. It is made of specially selected hardwood from the densest tropical forests creating exotic hardwood veneers. It has higher density compared with other plywood thereby reducing water absorption immensely. We make sure it helps prevent headaches that arise from warping, swelling and delamination.

TECHNICAL SPECIFICATIONS*

| Properties | Specified as per IS 303 : 1989 |

| Adhesive For Bonding | extra strong MUF Resin |

| Preservative Treatment | protection to every layer with glue |

| Glue Shear Strength | HMR Lab Test |

| Dry State | 1000 N 800 N |

| Mycological | 800 N 650 N |

| Wet State | 800 N 650 N |

| Water Resistance Test | |

| Stands soaking at 80°C for 8 hours and oven dry at 65°C for 8 hours. (More than 3 cycles) | |

| Conforms to IS 303 : 1989 |

SPECIFICATIONS

- High Moisture Resistant

- Resistant to termites and powdering problems

- Bonded with extra strong MUF resin for high moisture resistance

- Chemically treated to withstand tough climatic conditions

Applications

- Household furnitures

- Panelling

- Wardrobes and all interior decoration

UNIPLY FIRE RETARDANT

HIGH MOISTURE RESISTANT

This kind of plywood makes eminent sense in places likes theatres or malls where fire risk needs to be reduced. The hardwood panels have undergone vacuum-cum-pressure impregnation which creates a protective layer in case of a fire. However being fire retardant is not the only unique property, it also resists wood destroying elements like fungi, termites and borers.TECHNICAL SPECIFICATIONS*

| Properties | Specified as per BIS 710 : 1976 |

| Adhesive For Bonding | Phenol Formaldehyde Synthetic Resin |

| Treatment | Fire retardant treatment as per BIS 5539 : 1969 |

| Preservative treatment | Ammonium Phosphate/ Ammonium Sulphate/ Boron Compounds/ Combination of all three |

| Glue Shear Strength | Excellent |

| Dry State | 1215 N Avg. 990 N Min. Individual Avg. |

| Wet State | 900 N Avg. 720 N Min. Individual Avg. |

| Flammability | >20-30 mins |

| Flame penetration | >6-12 mins for every 6 mm thickness |

| Rate of burning | >15-20 mins |

| Conforms to the agreement between buyer and seller |

Specifications

- Resistant to ignition, spread and permeability of fire

- Treated with fire resistant chemicals at veneering stage to make it partially permeable

- Equipped against the risk of unchecked spread of fire

- Fungi, insect and borer resistant

APPLICATIONS

- Partition and panelling

- Office interiors

- Hotel Interiors

- Residential interiors

- Shops and commercial establishments

- Furniture

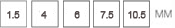

THICKNESS

UNIPLY FLEXIBLE

If you're a designer looking to create revolutionary pieces of furniture, then Uniply's flexiply should be an ideal pick. The flexible nature is due to its layers of thin plies which makes it easy to bend into various curved shapes quite easily. It is composed of tropical hardwood veneers and bonded with phenolic glue. Also you can be sure that its shape will be retained even after it's glued, laminated or veneered.

TECHNICAL SPECIFICATIONS*

| Composition | tropical wood, hot pressed with synthetic resin |

| Density | 700 Kg/m3 (approx.) |

| Bending Radii | For 4 mm thickness, 6" For 6 mm thickness, 9" For 9 mm thickness, 16" For 12 mm thickness, 24" |

| Elasticity | Cross grain 210 N/mm2 Long grain 6300 N/mm2 |

| Conforms to the agreement between buyer and seller |

APPLICATIONS

- Furniture

- Interior décor

- Installations

SIZE

- 2440 mm x 1220 mm and all other sizes against order

THICKNESS

UNIPLY ECOMATE BWR

BOILING WATER RESISTANT

Finally, an eco-conscious solution to using wood without harming the planet. Uniply's Ecomate BWR plywood is made from plantation timber acquired through social forestry, which implies that it will be replenished within 10 years. Apart from being eco- friendly, it is also boiling water resistant (BWR) and has been treated for termite and powdering problems.TECHNICAL SPECIFICATIONS*

| Properties | Specified as per BIS 303 : 1989 |

| Adhesive For Bonding | Phenolic glue as per CARB specification |

| Preservative treatment | Every layer protected with glue line protective chemicals |

| Specific Gravity | 650- 700 Kg / cm3 |

| Water Resistance Test | |

| Stands soaking at 100°C for 8 hours and oven dry at 65°C for 16 hours (3 cycle) | |

| Conforms to IS 303 : 1989 |

Specifications

- Boiling Water Resistant

- Resistant to termites and borers

- Preservative treated and bonded with phenolic glue

- Withstands all climatic conditions

- Made from environmentally sustainable, renewable wood

UNIPLY ECOMATE MR

MOISTURE RESISTANT

Ecomate MR, is a fitting choice for interior designers and architects who are keen on protecting the environment. The veneers are dried after soaking in eco-friendly inhouse formulated biodegradable organic compounds, to get maximum retention without affecting the wood. It is best suited for indoor applications, where the plywood is exposed to moderate levels of moisture.TECHNICAL SPECIFICATIONS*

| Properties | Specified as per IS 303 : 1989 |

| Adhesive For Bonding | Low emission glue as per CARB specification |

| Preservative treatment | Glue line protected |

| Glue Shear Strength | |

| Dry State | 1350 N Min. Avg. 1100 N (Min. Individual Value) |

| Wet State | 1000 N Min. Avg. 800 N (Min. Individual Value) |

| Specific Gravity | 650 Kg /Cubic Meter |

| Water Resistance Test | |

| Stands 3 hours soaking at 60°C | |

| Conforms to IS : 303-1989 |

Specifications

- Water resistant

- Preservative treated and bonded with low emission adhesives

- Made from environmentally sustainable, renewable wood